US-based Belden Inc. and global consulting firm Accenture have launched advanced physical AI solutions designed to improve workplace safety in factories and warehouses. The systems integrate AI, digital twins, and time-sensitive network infrastructure to monitor hazards and protect workers in real time.

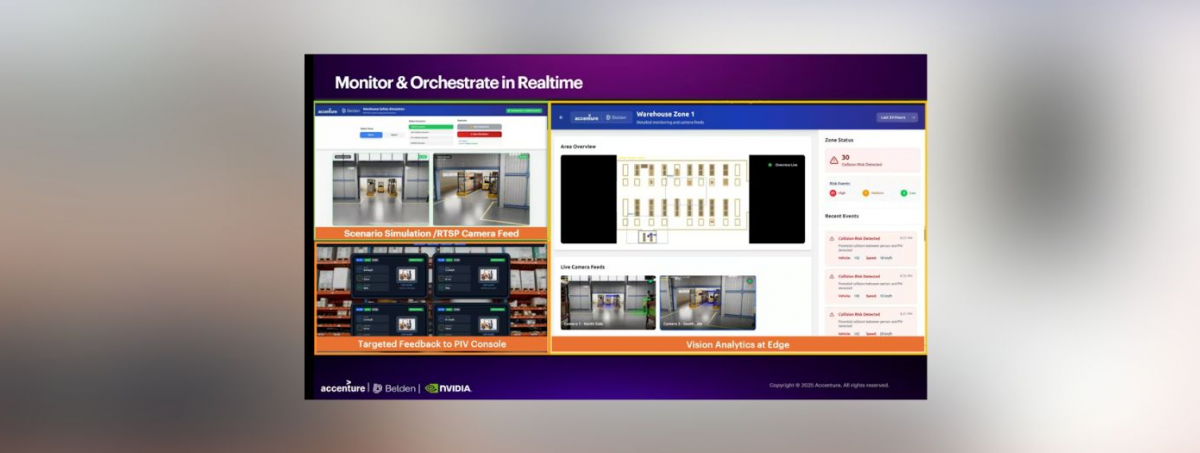

The new system includes Belden’s virtual safety fence, developed using Accenture’s Physical AI Orchestrator platform. It leverages NVIDIA Omniverse and NVIDIA Metropolis libraries to create digital twins that map industrial environments in real time. Using computer vision and closed-loop control, the system can automatically pause robotic operations when a person enters a hazardous area, preventing collisions or injuries.

Belden’s time-sensitive networking (TSN) technology provides the backbone for this innovation. TSN enables synchronised video streams from multiple cameras with microsecond precision, ensuring accurate tracking of workers and machinery on the factory floor. This infrastructure supports safety applications requiring instant response times without disrupting operational efficiency.

German Fernandez, Belden’s vice president for ecosystem partner programmes, said the company is evolving from selling connectivity products to delivering end-to-end industrial safety solutions. Ramalingam Hariharan, managing director at Accenture, highlighted that physical AI can protect workers while maintaining the flexibility modern manufacturing demands.

The collaboration combines Belden’s expertise in industrial network infrastructure and cybersecurity, NVIDIA’s accelerated computing and simulation technologies, and Accenture’s capabilities in physical AI, manufacturing automation, and system integration. Together, they aim to offer manufacturers scalable safety systems that can be implemented using existing factory infrastructure, reducing downtime and improving compliance with safety regulations.

Discover how Belden and Accenture are shaping safer industrial environments with AI-powered solutions in the full story.

.png)